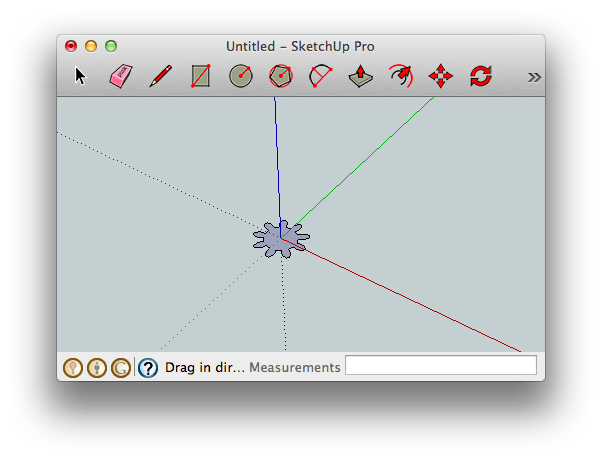

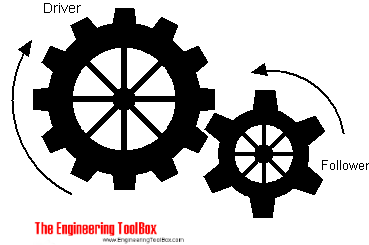

For example, Wade’s geared extruder has 11 teeth on the pinion and 39 teeth on the gear wheel. This helps to distribute lubricant and reduce ware. By having an odd number of teeth each tooth will meet a different counterpart on every rotation. However, an even number of teeth will result in the same pair of teeth meeting over and over again. However, your gear with more teeth would need need to be twice the size in order to have the same sized teeth.īy choosing an even number of teeth you have a range of different exact gear ratios. If you desire a gear ratio of 2:1 then your gear wheel will have twice as many teeth as your pinion. The number of teeth on your small gear (pinion gear) relative to your large gear (gear wheel) will determine the gear ratio. From the dialogue box you are presented with three options. Then open sketchup and choose ‘Involute Gear’ from the draw menu. This plug-in was not produced by me and all credit goes to Cadalog Inc for writing this very useful tool. To begin with, download the involute gear plugin and copy it to your sketchup plugin directory. For an introduction to sketchup see the sketchup related links this page.Ī collection of the gears seen in this page can be downloaded from the 3d warehouse. For a good introduction in general gear design see here. The following is a guide for designing gears in sketchup for 3D printing, CNC milling or similar.

Restart sketchup and then access it from the “Draw” menu. Just copy the plugin to your Sketchup plugins directory Eg: C:\Program Files (x86)\Google\Google SketchUp 8\Plugins or see here for newer sketchup versions). If you have trouble with this copy on older sketchup versions then try the original file which can be found here. This version has been updated to work with the newer versions of sketchup. For a copy of the plugin please see this link as the original owner appears to have moved the site.

0 kommentar(er)

0 kommentar(er)